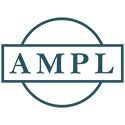

Knitting

Our knitting team comprises of highly capable individuals with developments going on continuous basis for our clients.

We have latest up to date Dragon circular knitting machines.

Cutting

We have a proactive cutting team with the main objective of quality with efficient flow of production without any pause.

Stitching

We have one of the latest precious computerized single needle, Overlock, Bartack etc.

Washing & Dyeing

We have installed latest Turkiye INFO-TEKS front loading washing and dyeing machines at our facility which are more than enough for our production capacity. The water fall circulation system ensures 1:2 – 1:4 Liquor ratio for all washing processes (including stone washing).

Embroidery

We have inhouse embroidery machines with enough capacity to easily fulfill our order requirements.

Quality Control

The main objective of our company at every stage of production is to maintain the highest level of quality which we have ensured our clients over the past 2 decades. International quality control models are followed at every level with giving the best outcome of the final product.

Packing

We have a dedicated packing team which makes sure all client requirments are met.

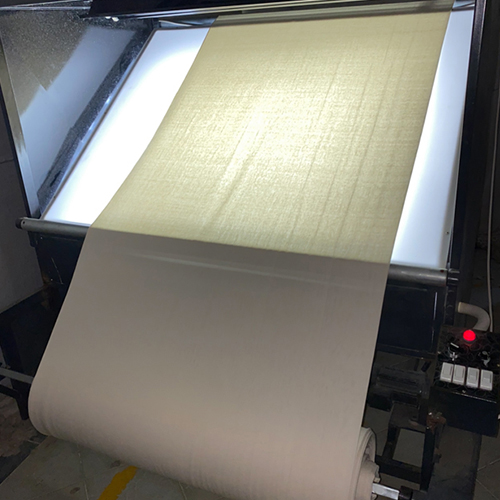

Water Treatment Plant

Water treatment is a process which is mandatory, as an organization we at AMPL have installed Effluent Treatment Plant or ETP water treatment method which is particularly designed to purify garment dyeing waste water for its reuse and it’s aim is to release safe water to the environment from the harmful effect caused by the effluent.

We have also installed RO plant with a capacity of 25000 gallons a day. So water first gets purified from RO and goes to the dyeing unit. Any waste water after dyeing is re used through the ETP and lastly the waste water is processed to remove any toxics which are harmful to the environment and then is released.